The 5 Secret Tests That Prove Your Rugged PC Will Last 5+ Years

The Core Investment: Durability Beyond Standard Consumer Devices

For businesses operating in demanding conditions—from high-traffic warehouses and manufacturing floors to extreme outdoor field service—a computer is more than just a tool; it's a critical investment. When an industrial terminal device fails, productivity halts. That's why the fundamental measure of any industrial-grade PC is its enduring reliability and resilience.

Unlike standard consumer laptops and tablets that are prone to failure from simple wear and tear, rugged computing solutions like those from ONERugged are built with longevity in mind. But how can we quantify this durability?

At the ONERugged Extreme Durability Lab, every device undergoes a stringent series of mechanical and physical tests designed to simulate over five years of relentless, real-world operational stress. We meticulously push components like interfaces, input mechanisms, and chassis integrity to their absolute breaking point to ensure your device delivers dependable performance, year after year.

ONERugged's Rigorous 5-Point Mechanical Endurance Protocol

Our comprehensive testing protocol guarantees that the core components, which often fail first on commercial devices, will stand the test of time on our rugged laptops and tough tablets.

1. The 10,000-Press Button Reliability Check

In dynamic work settings, physical buttons are subjected to constant, forceful usage. This test verifies the longevity of every programmable key.

-

The Trial: A button life tester applies 700g of consistent force to each physical button, cycling the press 10,000 times while the rugged device remains powered.

-

The Assurance: Post-test analysis confirms zero visible surface degradation, cracking, or loss of tactile sensitivity. This equates to over five years of usage, pressing a button approximately five times daily without expecting mechanical failure.

2. Million-Keystroke Torture Test for Rugged Keyboards

The keyboard serves as the primary human-machine interface on our rugged notebooks and is thus a major point of wear. We ensure it maintains its responsiveness throughout its service life.

-

The Trial: Our keystroke testing machine delivers a consistent 150g force across the keys for 1,000,000 total keystrokes over several days.

-

The Assurance: Professional diagnostics verify that all sensitivity and responsiveness indicators remain within optimal operating parameters. For the average worker, this keyboard durability comfortably corresponds to a service life exceeding five years.

3. Hinge Lifecycle Verification: 20,000 Cycles of Trust

A robust hinge is critical for the long-term integrity of a rugged laptop. A loose or compromised hinge can lead to screen damage or alignment issues.

-

The Trial: The hinge is repeatedly opened and closed 180 degrees for a total of 20,000 cycles. Detailed inspections are performed at 5,000-cycle intervals to monitor for stiffness, looseness, or structural damage.

-

The Assurance: No functional or structural anomalies are detected. For ten opening and closing actions per day, the rugged PC hinge lifespan is assured for well over five years.

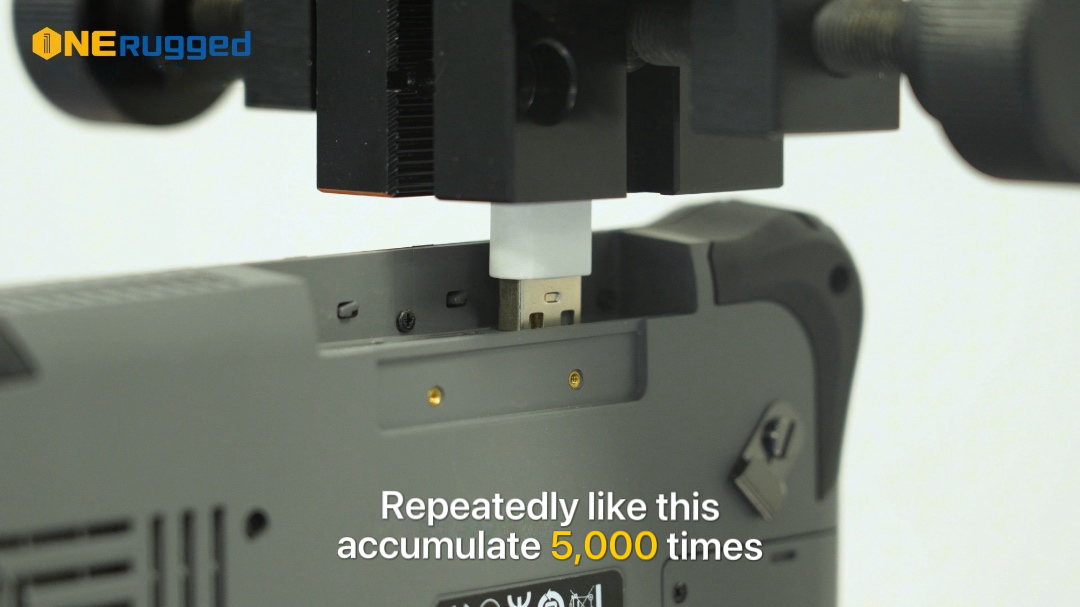

4. I/O Port Resilience: 5,000 Cycles of Continuous Plug-and-Play

In a connected field environment, frequent docking, charging, and data transfer via I/O ports (e.g., USB, DC, HDMI, SIM, TF slots) is inevitable. Loose ports compromise connectivity and data security.

-

The Trial: An automatic insertion tester cycles each essential interface and card slot through 5,000 insertions and removals.

-

The Assurance: All ports maintain their integrity, ensuring continued connectivity and device recognition with zero failures. This confirms the reliability of the I/O system under scenarios involving up to three daily plug/unplug actions for at least five years.

5. Preventing Catastrophe: The 9-Point Structural Pressure Audit

Accidental pressure—from being compressed in a transit bag to an unexpected impact—can instantly destroy an unprotected device. This test verifies the chassis's structural fortitude.

-

The Trial: A 10mm flat press head applies a vertical force of 5 kgf (kilograms-force) ten times to nine different stress points across the display and back cover.

-

The Assurance: The rigorous structural pressure test confirms that the chassis and screen remain completely undamaged and deformation-free, verifying the rugged tablet’s superior resistance to accidental crushing or collision during transport.

The ONERugged Promise: Long-Term Performance for Your Business

At ONERugged, our commitment to quality is proven, not just promised. These rigorous mechanical and physical endurance protocols unequivocally demonstrate that our industrial mobile computers meet and far exceed standard industry requirements.

By choosing an ONERugged device, you are not just purchasing a piece of equipment; you are securing a tool that offers long-term, predictable reliability for five years or more. This peace of mind means less downtime, reduced maintenance costs, and a guaranteed return on your rugged technology investment.

Frequently Asked Questions (FAQ)

1. Which specific ONERugged product lines undergo this 5-point durability testing?

A: All core product lines designed for long-term industrial deployment are subjected to these tests, including our Rugged Tablets (M-series), Rugged Notebooks (N-series), Vehicle PCs (V-series), and specialized Panel PCs (P-series). This comprehensive approach ensures that every device, from a warehouse management tablet to a transportation vehicle PC, meets the same high standard of endurance.

2. Does the 5-year reliability estimate mean the device is covered by a 5-year warranty?

A: The 5-year estimate is a statement of our verified mechanical lifespan under normal industrial use, based on our internal testing data. While it assures long-term performance, standard warranty coverage is subject to the specific terms and conditions outlined in your purchase agreement. We encourage customers to inquire about our extended service and maintenance options for complete long-term protection.

3. Is this testing performed on every single unit, or just on prototypes?

A: The 5-point protocol described is a standard procedure for validating the design and manufacturing quality of our prototype and production samples. Furthermore, all manufactured units undergo rigorous quality control checks, including final functional testing and random sampling, to ensure they consistently meet the certified design standards established by these extreme durability trials.

4. How does investing in a 5-year durable PC translate to cost savings for my business (ROI)?

A: High durability directly leads to a significantly better Return on Investment (ROI). By purchasing a device certified to perform reliably for 5+ years, you minimize frequent replacement costs, eliminate unexpected downtime that costs employee wages and lost productivity, and reduce IT maintenance expenditure. A longer device lifespan means lower Total Cost of Ownership (TCO).

5. What is the difference between these tests and standard military specifications like MIL-STD-810H?

A: Our mechanical endurance tests (buttons, hinges, ports) go beyond the environmental and shock/vibration requirements of the MIL-STD-810H standard. While MIL-STD-810H focuses on survivability in extreme environmental conditions (e.g., drop, vibration, temperature), our protocol focuses on guaranteeing the functional lifespan and long-term mechanical integrity of input mechanisms, which are crucial for daily operation. Both sets of standards ensure maximum durability.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.